What's butcher block?

Butcher block is a name that originated in butcher shops. The chopping blocks used in butcher shops were large blocks of wood that were created from laminating smaller pieces of wood together. This style of wood became known as a butcher block and now is used in everything from home kitchens to furniture.

How butcher block is made?

Wood is cut into strips 1.75 inches deep with varying heights depending on the application. These strips are finger jointed together. Finger joints look similar to extending all your fingers on both your hands, then fitting your fingers from each hand between each other. The finished pieces are stacked and laminated together using a large press. Finally the finished block is sanded and finished with a sealer.

What is butcher block oil?

Butcher block oil is a food safe finishing oil used on butcher blocks to prevent the wood from drying out. There are different types of oil used on butcher blocks like mineral oil and pure tung oil. It is important to use oil and/or conditioner to prevent the butcher block from drying out and cracking.

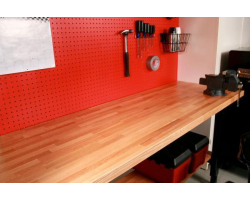

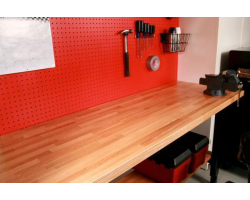

What is butcher block wood?

Many different types of wood can be used to make butcher blocks. Butcher block refers to the final product of long strips of wood being laminated together creating a specific look with the many different stacked grains.

What is butcher block conditioner?

Butcher block conditioner is used to seal the butcher block oil in the wood and keep the moisture out.

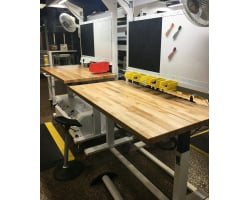

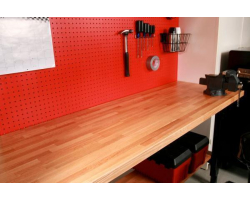

What is butcher block used for?

Originally butcher block was used in butcher shops as the chopping block to work on. They were typically very thick and heavy blocks that would end up with a concave curve after many years of working on them. These days butcher block is used in everything from residential kitchens for countertops, to cutting boards, and even furniture.

How to install butcher block countertop?

Installing a butcher block countertop has two important aspects to take into consideration. First, the butcher board needs to have air flow on both the top and the bottom surface. You do not want to put the butcher block countertop onto another flat surface because the restricted air flow can cause an imbalance in moisture from the top and bottom which will result in warping. If you are putting the countertop onto another surface, you’ll want to create an air gap between them which can be as simple as putting a few large washers down. Second, the butcher block will expand and contract depending on the humidity. The overall length is stable, but the depth will expand and contract as much as 3/16 of an inch. You will need to allow for this when you mount the countertop. This can be accomplished by drilling the mounting holes larger than the screws and placing washers over the screws so the countertop can expand and contract without being bound. If the countertop is not allowed to expand at the mounting point, it will warp as it changes size with the humidity.

Model: 67381

..

$1,023.99

Model: 70845

..

$1,120.99

Model: 67382

..

$1,140.99

Model: 70846

..

$1,272.99

Model: 67383

..

$1,257.99

Model: 70847

..

$1,415.99

Model: 67385

..

$1,528.99

Model: 70849

..

$1,702.99

Model: 67386

..

$1,692.99

Model: 70851

..

$1,983.99

Model: 70854

..

$1,900.99

Model: 70853

..

$2,328.99

Model: 81787

..

$60.99

Model: 81786

..

$78.99

Showing 1 to 14 of 14 (1 Pages)