CLICK HERE FOR PRINTABLE INSTRUCTIONS

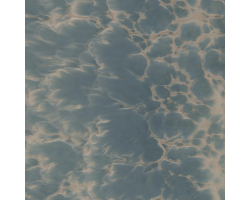

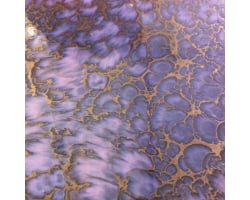

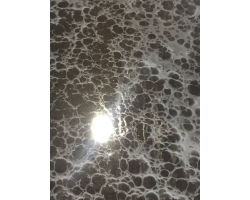

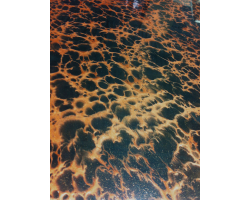

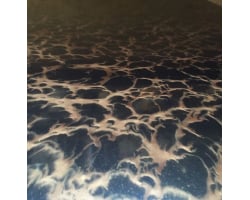

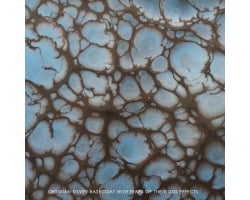

For a different style of epoxy floor, you may like what's called metallic epoxy. Metallic epoxy and the effects will create a unique and artistic look for your floor by layers that are applied to achieve superior durability, and that one of a kind look. This is a 100% solids epoxy that works with chemical reactions to make a creative design on your floor. It is a very high quality epoxy, but keep in mind this metallic epoxy does not like UV light, so if you get a lot of sunlight in your garage this metallic epoxy will fade. You can use this epoxy indoors, like in a basement. The only difference between using this epoxy indoors as opposed to a garage is the topcoat that is applied. Inside it's a high gloss topcoat and when it's applied there is very low odor and no flammability. It's also self leveling. In a garage it's an eggshell finish topcoat that you will roll on. When you purchase the metallic epoxy from Car Guy Garage you will be given the options of the square footage, and if it will be in an interior or a garage space. The only difference is the topcoat that is shipped with the kit.

Before you begin the process of applying the epoxy you need to take inventory of everything that has been delivered to you. There are usually multiple boxes which may have been shipped from multiple locations. So although you may have received a shipment, there may still be more on the way to you. Open up all the boxes and organize the chemicals so that you have each set of chemicals arranged for each step. Arrange the bottles of etch-and-clean first. Second, arrange the cans of WB primer with each A and B cans next to each other. Third, put the basecoat cans A and B next to each other along with the effects cans A and B next to each other. And finally open up and organize the topcoat. This way you can make sure everything was delivered before you begin. Let's go through all the steps to apply this metallic epoxy to your floor.

Let's go through all the steps to apply this metallic epoxy to your floor.

Step 1: Grind the floor

This is an important step that no one should skip, even if you have new concrete. You need a rough surface on the concrete so that the epoxy has something to grab. It should look similar to 100 grit sandpaper. You need to contact a local tool rental or hardware store to rent a floor grinder. Floor grinders either use water from a garden hose or suction from a vacuum to keep the dust down. You plug the machine in and walk it up and down the floor similar to walking a lawnmower. The hardest part about the floor grinder is getting it to your garage from the rental location. These are usually bulky machines but they are typically easy to operate.

Step 2: Etch and clean

The first chemical you use from the Car Guy Garage kits is etch and clean. This is a phosphoric acid solution that removes contaminants from the concrete. Pour it onto the concrete and use a stiff bristle brush to give the floor a good scrubbing. This acid should only have contact with the concrete for a maximum of ten minutes. Triple rinse it thoroughly with water (power washing is ideal) and allow the floor to dry a minimum of eight to ten hours before moving to the next step.

Step 3: Primer and Sealer

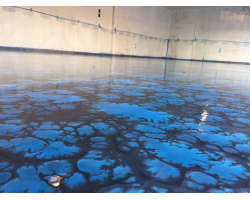

The next chemical you’ll be using does three things: it provides a primer bonding coat; seals the concrete from air and-or moisture coming from under the slab; and sets up the first color layer. What you're technically doing is using a colored waterborne epoxy as the primer so that you can get the final decorative look. The color of the waterborne epoxy used in this step will be different depending on the final result you're after.

You'll mix together part "A" and part "B" in a 5 gallon bucket. First empty all of part "A" into the bucket and slowly add part "B" while you are mixing. Once the two components are thoroughly mixed you have about 50 to 70 minutes to use it before it will become too hard.

It is best to use a three-eighths inch nap roller and a brush to cut in the edges. Start with the area furthest from the exit door and work your way toward the door. It has a very low viscosity so it’s easy to put down. One gallon will cover two-hundred-and-fifty square feet.

It should be applied in one even coat to completely cover and penetrate the surface. The finished look will depend on how porous the concrete is, the more porous the more textured it will appear.

Wait until you can walk on it (generally 7 to 10 hours) before you move to the next step. Application thickness and cooler temperatures can extend this time, so make sure it's completely dry before moving on.

Step 4: Apply the Epoxy basecoat

This step is extremely time sensitive. You have a limited amount of time to complete this step to get the proper uniform finished look. At 70 degrees Fahrenheit, you only have a 30 minute window to complete this step. The warmer the temperature, the quicker these chemicals will harden. If it's 90 degrees outside you'll only have a few minutes.

For applications larger than 200 square feet you want at least three people for this step. One person will mix material. One person will brush and roll. One person will apply the effects.

Do not start this step if anything is wet, it’s raining, or it’s very humid. You do not want condensation to settle on the epoxy coating during the application or curing process.

Let’s get started. First mark off 200 square foot sections on your floor. Because each epoxy base coat set covers 200 square feet, this gives you boundaries for how far one can should spread. You can use chalk on the primer coat to mark sections off.

Begin by painting in the corner furthest away from the exit of the room. Pour a small portion around the edges of the 200 square foot section you will be covering, and then pour the rest of the material onto the floor in ribbons making sure not to pour it outside of the chalked area. Once the material is out of the can completely, use a brush to cut in around any walls and use a three-eighths inch roller to aggressively move the material around. You need to work quickly! After the epoxy has been evenly spread out, quickly backroll the area with your roller in one direction to give it an even finish.

Immediately after applying the epoxy, apply the metallic effects.

Step 5: Applying the metallic effects

You have a maximum of 8 minutes after your epoxy base coat has been applied to use the effects, so work quickly, otherwise the effects won’t spread evenly.

You need to have the metallic effects ready to go before the other person applying the epoxy base coat is finished rolling out the 200 square foot chalked in section.

You will use two metallic effects sets (two cans of part “A” and two cans of part “B”) for each 200 square foot section of wet epoxy basecoat. These two sets will make two quarts of final mixed material, so you need to have a container that will allow you to mix them without spilling. A one gallon bucket works well.

Pour in two cans of the metallic effects part “A” and two cans of the metallic effects part “B” into the one gallon bucket. Mix them thoroughly by hand with a paint stir stick. These cans are pre-measured at a 2 to 1 mix ratio with the final mixed result of all four cans being two quarts.

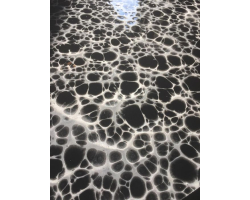

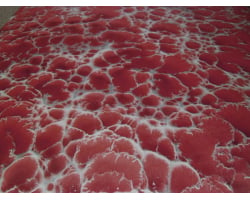

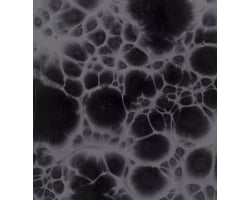

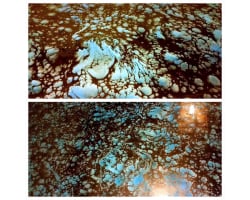

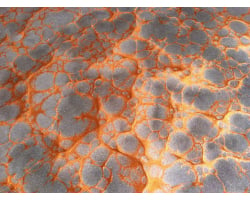

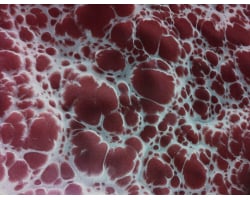

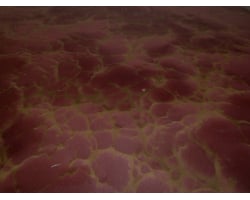

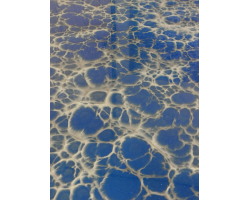

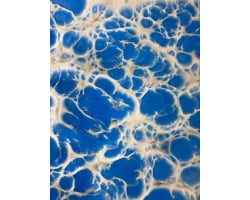

With your spiked shoes on, walk over the wet epoxy basecoat. Take a paint brush and saturate it in the effects mixture. With the paint brush bristle side down, sprinkle the effects onto the wet epoxy. This will leave drops and splatters of different sizes depending on brush size and saturation of the brush. Apply the effects as heavy as possible keeping the drops of effects close together. Overlapping of effects gives the floor a much more appealing and dramatic look.

The team effort of one person mixing, one person applying the base coat of epoxy, and one person applying the metallic effects needs to be kept in motion until the entire floor has been completed. Once the whole floor is complete, you can apply whatever effects you may have left wherever you see fit. Over the next few hours the effects will morph and spread.

You should not move to the next step until the floor is completely cured and hard. This will take a minimum of 14 hours. The “effects” areas are usually the last spots to harden, and they need to be completely hard, not soft, before you move onto the topcoat. You also should not exceed twenty-four hours before applying the topcoat. So the topcoat should be applied somewhere between 14 to twenty-four hours once the epoxy and effects have been applied.

Step 6: Topcoat for the garage

Step 6 has two versions depending on your application: the garage or the interior, because these are two different topcoats. If you're applying the topcoat inside, you can jump ahead to the next step 6. Now let's talk about using the topcoat for your garage.

The garage topcoat is a high-wear urethane. It comes as three parts that mixed together create one gallon and cover 600 square feet. For this step, you'll put your spiked shoes back on.

Start by pouring part "A" with part "B" into a five gallon bucket. Thoroughly mix them together. Continue to mix them and add in part "C" until you have a completely uniform mixture. You can use a paint stir stick or a slow speed power mixer, but avoid whipping air into the coating. Make sure they are mixed extremely well. Once mixed, you have one to two hours before it becomes too hard to roll out.

Pour the mixed material into a paint tray. Using a three eighths inch nap roller apply the topcoat at a rate of 600 square feet per gallon. Unlike the epoxy, you want to apply the topcoat by rolling out any excess material on the roller tray before you put the roller onto the floor so that you apply the material in thin, even coats. It is almost impossible to over-roll this material, so if any area is uneven, re-roll it until it's uniform. You also want to re-mix the material as you apply it so it stays mixed throughout the application process.

Once you've coated the entire floor, without applying any pressure, re-roll the whole floor in the opposite direction. This will help blend in any roller and overlap marks.

At 70 degrees, the topcoat will be dry to the touch in three to six hours. It'll be ready for light foot traffic in fourteen to twenty-four hours. It will be fully cured in three to five days.

Step 6: Topcoat for the interior

The interior version of the metallic epoxy kit comes with a topcoat that is different than the garage version. If you've got the garage kit, you can skip ahead to the wrap up. If you've got the interior topcoat, you're in the right spot. Let's talk about the interior topcoat.

The interior topcoat is a 100% solids epoxy with low odor, no flammability, and is self-leveling. When applied at 100 to one-hundred-twenty-five square feet per gallon, it will self-level to a glasslike surface.

This topcoat comes as 1 gal of part "A" (the resin) and a half gallon of part "B" (the hardener). They are in pre-measured kits and should be mixed as supplied in the kit. Pour both part "A" and "B" into a five gallon bucket. Mix them well by hand or with slow speed mixing equipment until the material is thoroughly mixed and streak free. It's very important it's mixed extremely well, but do not whip air into it. After mixing, transfer the mixed material to another five gallon bucket, and mix it again. Once it's been mixed in the second bucket, it's ready to be applied.

The mixed material can be applied by brush, roller or a serrated squeegee and then back rolled. You'll put your spiked shoes back on to apply it. At 70 degrees, you have twenty to thirty minutes to apply the topcoat before it becomes too hard. It will be dry to the touch in six to eight hours. Ready for light foot traffic in fourteen to eighteen hours. And fully cured in two to seven days.

The Wrap Up

From start to finish you can complete the entire epoxy application process in 4 days.

Day 1: Grind; and then Etch-and-Clean, the floor.

Day 2: Apply the sealer and primer

Day 3: Apply the epoxy and effects

Day 4: Apply the topcoat.

You can walk on it the next day and drive a car on it about 7 days later. So depending on the weather which impacts curing times, you’ll basically be parking your car outside for about 11 days.

Essential Tools:

- A stiff bristle brush to scrub in the etch and clean

- Three 3/8" nap rollers (1 for the Primer, 1 for the epoxy basecoat, and one for the topcoat)

- Roller frames and Paint Trays

- Four 3" inch brushes (for edging and drizzling effects)

- One or Two 5 gallon buckets (one for the primer which you can clean with water, and one or two for the topcoat depending; the garage topcoat needs one bucket; the interior topcoat needs two )

- One 1 gallon bucket (for the metallic effects)

- Chalk (to mark the floor)

- Drop-cloth (for the mixing station)

- Spiked Shoes

- Rubber gloves

- Rags

- Masking tape

- Stir sticks

The primer coat is water based, so after applying it, you can clean brushes, rollers and buckets with soap and water.

The epoxy basecoat and topcoat will need solvent to be cleaned off. You should be able to pick up some Xylene at your local hardware store.

Remember it's best to have at least three people doing the project, especially when it comes to the epoxy basecoat and effects. Take this into consideration with the supplies listed, you may want additional rollers, brushes, buckets, spiked shoes, and gloves if you have additional people helping.

If you have any questions, give us a call at 800-736-9308 or email sales@carguygarage.com We carry all the products you need to epoxy your garage floor in easy to purchase kits set up by square footage

PDF Data Sheets