- Est delivery : May 7 - May 24

- Model: 17604

Available Options

Get your coupon code

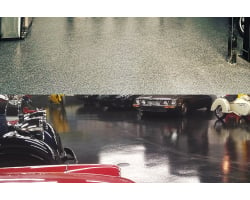

Our 1,200 sq ft Industrial Grade Solvent-based Epoxy Floor Coating Kit stands as the most cost-effective solution for those seeking an industrial chemical epoxy application. By combining superior durability, customizable aesthetics, and an essential topcoat, this kit delivers unparalleled value. Its comprehensive coverage, resistance to wear and tear, and easy maintenance ensure a long-lasting, high-quality finish without the need for frequent reapplications or costly repairs. Ideal for both residential and commercial spaces, it offers a professional-grade appearance and performance at a fraction of the cost, making it the smart choice for savvy consumers aiming for both quality and affordability in their flooring projects.

For the best results with your Industrial Grade Solvent-based Epoxy Floor Coating Kit, we highly recommend watching our comprehensive 10-minute instructional video. This guide walks you through each step of the application process, ensuring you achieve a professional-grade finish. To further assist you, we've provided a PDF transcript of the video. We encourage you to print this document and keep it handy as you work, allowing you to follow along with ease and confidence. This resource is designed to make your DIY project as straightforward and successful as possible.

Kit Contents:

- 3 of the Devoe Pre-prime 167 Primer (1 Gallon)

- Coverage of up to 500 square feet per gallon

- Ensures a strong and uniform adhesion base for the subsequent epoxy layers, enhancing their durability and finish.

- Seals the concrete from air and/or water that may be coming up from under the concrete slab.

- Reduces the amount of epoxy needed by sealing the porous surface.

- Technical Data Sheet

- 3 of the Devoe Devran 224HS Solvent Based Epoxy (2 Gallon Kit)

- Coverage of up to 200 square feet per gallon which is 400 square feet per 2 gallon kit

- A robust epoxy kit that delivers an industrial-grade coating to protect and beautify your garage floor.

- High-solid formula offers unparalleled strength and a stunning finish resistant to chemicals, impacts, and abrasions.

- Provides a thick, durable layer that withstands heavy traffic and extreme conditions.

- Technical Data Sheet

- 3 of the Devoe Devthane 379 Clear Topcoat (1 Gallon)

- Coverage of up to 400 square feet per gallon

- A premium clear coat designed to offer an extra layer of protection and shine to your epoxy-coated garage floor.

- Clear urethane coating seals the epoxy layer underneath, providing a scratch-resistant and UV-protected surface.

- Guards against fading and yellowing caused by sunlight exposure.

- Extends the lifespan of your epoxy coating by providing an additional protective layer.

- Ensuring that your investment is protected and can be easily maintained over the years. Minor scratches can often be resolved by lightly sanding the surface, wiping it down with xylene, and reapplying the topcoat, restoring your floor's pristine appearance with minimal effort.

- Technical Data Sheet

Important Considerations:

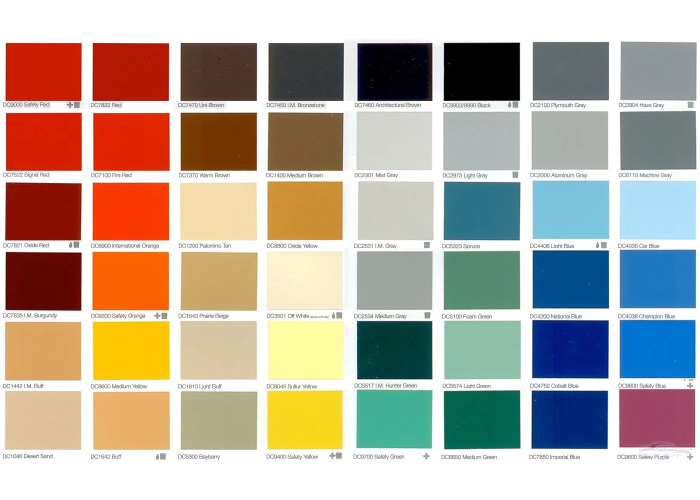

- Custom Color Tinting: Products cannot be returned due to our custom color tinting process, which is completed after the order is placed. Please make your color selection carefully.

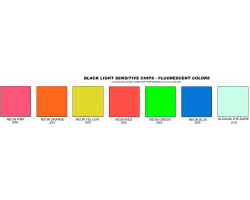

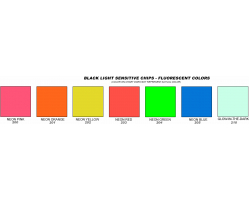

- Bright Colors: For vivid or bright colors, two coats of epoxy may be necessary to achieve full coverage. Additional 2-part epoxy coatings are available for purchase. Note that some colors may require more pigment, incurring an additional charge.

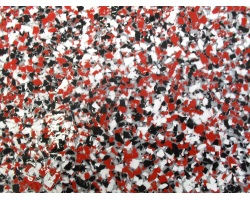

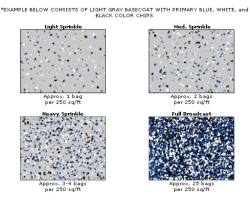

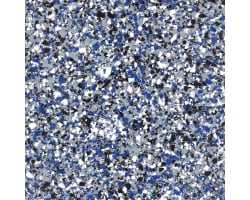

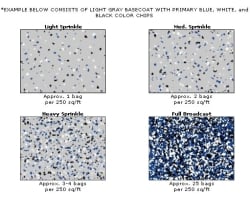

- Epoxy Paint Chips: Not included in the kit, but available for purchase to enhance the floor's texture and appearance.

- Storage and Use: For optimal results, use this product within 6 months of purchase and store it indoors at an optimal temperature of 70 degrees, away from sunlight.

- Shipping Restrictions: Cannot be shipped to California due to local regulations.

This kit is meticulously crafted for those seeking a professional-grade flooring solution that combines longevity with customizable aesthetics. Whether upgrading a home garage, workshop, or commercial space, our Industrial Grade Solvent-based Epoxy Floor Coating Kit is designed to deliver unmatched quality and style.